| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | PAM-XIAMEN |

| Payment Terms : | T/T |

| Supply Ability : | 10,000 wafers/month |

| Delivery Time : | 5-50 working days |

N Type , InP(Indium Phosphide) Substrate,3”, Prime Grade -Compound Semiconductor

PAM-XIAMEN offers InP wafer – Indium Phosphide which are grown by LEC(Liquid Encapsulated Czochralski) or VGF(Vertical Gradient Freeze) as epi-ready or mechanical grade with n type, p type or semi-insulating in different orientation(111)or(100).

Indium phosphide (InP) is a binary semiconductor composed of indium and phosphorus. It has a face-centered cubic (“zinc blende”) crystal structure, identical to that of GaAs and most of the III-V semiconductors.Indium phosphide can be prepared from the reaction of white phosphorus and indium iodide[clarification needed] at 400 °C.,[5] also by direct combination of the purified elements at high temperature and pressure, or by thermal decomposition of a mixture of a trialkyl indium compound and phosphide. InP is used in high-power and high-frequency electronics[citation needed] because of its superior electron velocity with respect to the more common semiconductors silicon and gallium arsenide.

N Type, InP Substrate, 3”, Prime Grade

| 3"InP Wafer Specification | ||||

| Item | Specifications | |||

| Conduction Type | N-type | N-type | ||

| Dopant | Undoped | Sulphur | ||

| Wafer Diameter | 3" | |||

| Wafer Orientation | 100±0.5° | |||

| Wafer Thickness | 600±25um | |||

| Primary Flat Length | 16±2mm | |||

| Secondary Flat Length | 8±1mm | |||

| Carrier Concentration | ≤3x1016cm-3 | (0.8-6)x1018cm-3 | (0.6-6)x1018cm-3 | N/A |

| Mobility | (3.5-4)x103cm2/V.s | (1.5-3.5)x103cm2/V.s | 50-70cm2/V.s | >1000cm2/V.s |

| Resistivity | N/A | N/A | N/A | >0.5x107Ω.cm |

| EPD | <1000cm-2 | <500cm-2 | <1x103cm-2 | <5x103cm-2 |

| TTV | <12um | |||

| BOW | <12um | |||

| WARP | <15um | |||

| Laser Marking | upon request | |||

| Suface Finish | P/E, P/P | |||

| Epi Ready | yes | |||

| Package | Single wafer container or cassette | |||

Most test wafers are wafers which have fallen out of prime specifications. Test wafers may be used to run marathons, test equipment and for high-end R & D. They are often a cost-effective alternative to prime wafers.

| Electron Hall mobility versus temperature for different doping

levels. Bottom curve - no=Nd-Na=8·1017 cm-3; Middle curve - no=2·1015 cm-3; Top curve - no=3·1013 cm-3. (Razeghi et al. [1988]) and (Walukiewicz et al [1980]). |

| Electron Hall mobility versus temperature (high temperatures): Bottom curve - no=Nd-Na~3·1017 cm-3; Middle curve - no~1.5·1016 cm-3; Top curve - no~3·1015 cm-3. (Galavanov and Siukaev[1970]). |

µn = (4.2÷5.4)·103·(300/T) (cm2V-1 s-1)

| Hall mobility versus electron concentration for different

compensation ratios. θ = Na/Nd, 77 K. Dashed curves are theoretical calculations: 1. θ = 0; 2. θ = 0.2; 3. θ = 0.4; 4. θ = 0.6; 5. θ = 0.8; (Walukiewicz et al. [1980]). Solid line is mean observed values (Anderson et al. [1985]). |

| Hall mobility versus electron concentration for different

compensation ratios θ =Na/Nd, 300 K. Dashed curves are theoretical calculations: 1. θ = 0; 2. θ = 0.2; 3. θ = 0.4; 4. θ = 0.6; 5. θ = 0.8; (Walukiewicz et al. [1980]). Solid line is mean observed values (Anderson et al. [1985]). |

µ=µOH/[1+(Nd/107)1/2],

where µOH=5000 cm2V-1 s-1,

Nd- in cm-3 (Hilsum [1974])

At 300 K, the electron Hall factor rn≈1 in n-InP.

for Nd > 1015 cm-3.

| Hole Hall mobility versus temperature for different doping (Zn)

levels. Hole concentration at 300 K: 1. 1.75·1018 cm-3; 2. 3.6·1017 cm-3; 3. 4.4·1016 cm-3. θ=Na/Nd~0.1. (Kohanyuk et al. [1988]). |

µpH~150·(300/T)2.2 (cm2V-1 s-1).

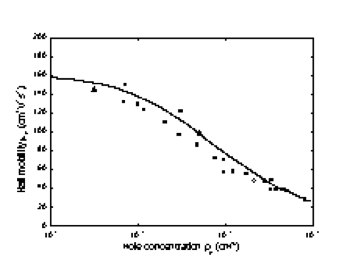

| Hole Hall mobility versus hole density, 300 K (Wiley [1975]). The approximate formula for hole Hall mobility: µp=µpo/[1 + (Na/2·1017)1/2], where µpo~150 cm2V-1 s-1, Na- in cm-3 |

At 300 K, the hole factor in pure p-InP: rp~1

InP based lasers and LEDs can emit light in the very broad range of 1200 nm up to 12 µm. This light is used for fibre based Telecom and Datacom applications in all areas of the digitalised world. Light is also used for sensing applications. On one hand there are spectroscopic applications, where a certain wavelength is needed to interact with matter to detect highly diluted gases for example. Optoelectronic terahertz is used in ultra-sensitive spectroscopic analysers, thickness measurements of polymers and for the detection of multilayer coatings in the automotive industry. On the other hand there is a huge benefit of specific InP lasers because they are eye safe. The radiation is absorbed in the vitreous body of the human eye and cannot harm the retina. InP lasers in LiDAR (Light Detection And Ranging) will be a key component for the mobility of the future and the automation industry.

PAM-XIAMEN is your go-to place for everything wafers, including InP wafers, as we have been doing it for almost 30 years! Enquire us today to learn more about the wafers that we offer and how we can help you with your next project. Our group team is looking forward to providing both quality products and excellent service for you!

|

|